“Are you interested in the whole body or the neuro? And would you like fries and a Coke with that?”

“Are you interested in the whole body or the neuro? And would you like fries and a Coke with that?”

By Mike Darwin

Introduction

A short while ago, I hosted 3 visitors from the Russian cryonics organization KrioRus. During my visit with them in Moscow two and a half years previously, I had exhorted them to visit the US and see first-hand any hub of cryonics activity there, so that that they could see and learn for themselves what cryonics was really like, and how it was actually being pursued in the US. When I wrote to Alcor President and CEO Max More to try and schedule a visit on short notice, I jokingly included the aside that if I was not permitted to be on premises, I would go elsewhere… It was intended to be a humorous reference to a time in the not so distant past when I was not allowed into Alcor because my homosexuality was “unacceptable” to a former Alcor President (apparently being incompatible with his religious beliefs).

To my considerable surprise, Max took this remark seriously, and polled the Alcor Board on the matter. Surprise was replaced with shock when I subsequently learned that Alcor Director Saul Kent had expressed concerns that my visit to Alcor accompanying the Russians would be used as tool to “attack Alcor.” I still find this shocking, but depending upon how you define attack, maybe Saul was closer to the truth than I imagined possible. I’ve since been told that apparently there were speculations that “touring Russians” might be just an excuse of some kind to gain entry to Alcor.[1] Why this should be necessary is still a mystery to me, since as far as I knew I could visit by making by an appointment, presumably like anyone else.

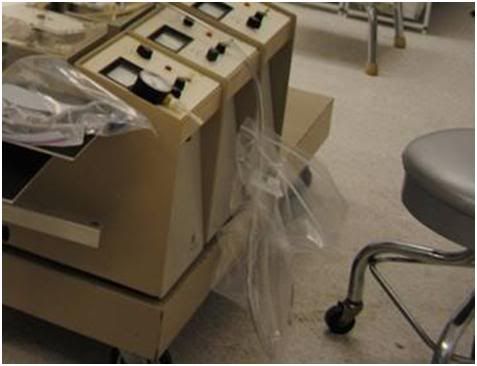

Figure 1: The Alcor Mobile Advanced Rescue Cart (MARC), a portable extracorporeal support platform.

I saw quite a few unexpected things at Alcor, such as that the MARC is no longer in use and lies covered in dust (not even tarped) and laden with ‘junk’ in the ambulance bay; it has been replaced by waist high PIB fabricated from stainless steel. All of which begs the point of why a hugely complex and costly technological platform, in the form of a mobile operating room was developed, if it isn’t going to be used for extracorporeal support?

Figure 2: Left to right, Danila Medvedev, President of the Russian Transhumanist Association, Max More, Ph.D., President and CEO of Alcor and Valerija Pride, President of KrioRus. Photo by Stanislaw Lipin; courtesy of KrioRus.

A Long History of Serious Deficiencies in Patient Care

Shortly after he took office, I sent Max the 100+ plus page “Report of the Committee to Evaluate Alcor Procedures” which was presented to the Alcor Board of Directors on 04 April, 2002. This report came about because Saul Kent invited me over to his home in Woodcrest, California to view videotapes of two Alcor cases which troubled him – but he couldn’t quite put his finger on why this was so. What I saw shocked and disgusted me. Patients were being stabilized at a nearby hospice, transported to Alcor (~20 min away) and then CPS was discontinued, the patients were placed on the OR table and, without any ice on their heads, they were allowed to sit there at temperatures a little below normal body temperature for 1 to 1.5 hours, while burr holes were drilled, and the neck vessels were cannulated. Distilled water was being used to irrigate the brain and burr holes were done with a wood burr and electric drill with no cooling of the bone under the burr – smoke could be seen coming from the burr wound! Since the patient had no circulation to provide blood to carry away the enormous heat generated by the action of the burr on the bone, the temperature of the underlying bone (and brain) must have been high enough to literally cook an egg.

In one case, a patient’s head was removed in the field and, because they had failed to use a rectal plug, the patient had defecated in the PIB. The result was that feces had contaminated the neck wound, and Alcor personnel were seen pouring saline over the stump of the neck whilst holding the patient’s severed head over a bucket trying to wash the fecal matter off the stump. These are just a few of the grotesque problems I observed.

As a consequence, a “blue ribbon” Committee was put together to comprehensively review Alcor patient videos and records, and to make a field inspection of the Alcor facility. This Committee produced a comprehensive report and presented it to the Alcor Board. [Darwin, M., et al., Report of the Committee to Evaluate Alcor Procedures, Presented to the Alcor Board of Directors on April 4th, 2002.] Max More knew nothing of this until I sent him a copy after he was President for about one and a half months.

A Profound and Fundamental Error Unendingly Repeated

A short while later, Alcor published the first detailed case report since the A-1097 case report was published in 2006. A careful reading of this case report which is available at http://www.alcor.org/Library/pdfs/casereportA2435.pdf discloses that there is something terribly wrong that happens during this case, but unless you really understand cryonics as medicine, you are not likely to see it. The patient was pronounced at 6:58 PM and was transported to Alcor packed in ice while receiving CPS with the LUCAS. At ~ 8:42 PM, 1 hour and 42 minutes later, a median sternotomy is begun (excerpt from the case report, emphasis mine):

Continuation of CPS

Move to surgical table

7. Surgical Procedures

Manual CPS was continued on the patient while fresh ice was brought in from Alcor’s ice machine. The existing ice was removed from on top of the patient and she was pulled out of the ice bath and placed on the OR surgical table at 8:11 pm.

Testing of the sternal saw prior to the surgery revealed that the flexible shaft had frozen up. The problem was handed to Richard to deal with, and he had it unfrozen in a few minutes. The shaft was subsequently disassembled and lubricated.

The patient’s head was shaved to prep for the burr holes to be drilled. These are used to monitor the temperature of the patient’s brain as well as a way to visually watch for swelling. While the burr holes were being drilled using a craniotome perforator, Aaron prepped the patient’s sternum with Betadine, an antiseptic agent used topically to destroy microbes. Dr. McEachern cleaned each of the burr holes as they were completed. At 8:42 PM, she stood on a step stool to gain a higher position above the patient in order to perform a median sternotomy. This is a procedure in which a vertical inline incision is made along the sternum, after which the sternum itself is divided to provide access to the heart for cannulation. Dr. McEachern cut through the skin of the chest with a scalpel. The guide of the saw blade was placed below the sternum. Richard operated the foot pedal on the floor as she guided the saw up the sternum. She talked through the procedure, step by step, to Aaron so he could gain additional training in its operation and application. After the sternum separation was completed, the chest was opened with Finochietto spreaders and the pericardial sac was exposed. Access to the heart was accomplished by cutting through the pericardium.

Dr. McEachern performed an arterial cannulation of the heart by sewing a purse-string suture into the wall of the aortic arch, puncturing the vessel within the purse-string, and advancing and securing the catheter. She then repeated this process for venous cannulation of the heart, going into the right atrium and advancing the cannula into the inferior vena cava. This process took approximately one hour and was completed at 9:48 PM. A thermocouple was placed under the dura through the burr hole at 3.0 hours post-arrest. Brain temperatures were taken under the dura and beneath the brain (nasopharyngeal).

Now the washout could begin. This process is used to replace the patient’s blood with cryoprotectant. The extracorporeal perfusion circuit had been primed with B1 base perfusate solution prior to the surgery and was being circulated through the bypass loop. When cannulation was complete, the circulation was transferred from the bypass loop into the cannulas. The circuit was switched from closed to open circulation and the blood was washed out of the patient’s vascular system, the visual blood concentration going from opaque to light pink.

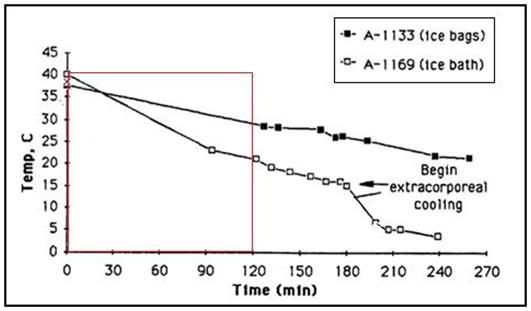

The graph of below shows a typical patient’s cooling rate in the PIB.

Figure 3: The red-boxed areas of the two cooling curves above show the likely temperature range a patient would have cooled to during 1 hour and 44 minutes of closed chest cardiopulmonary supported external cooling using ■ ice bags or □ Portable Ice Bath (PIB) cooling.

Figure 3: The red-boxed areas of the two cooling curves above show the likely temperature range a patient would have cooled to during 1 hour and 44 minutes of closed chest cardiopulmonary supported external cooling using ■ ice bags or □ Portable Ice Bath (PIB) cooling.

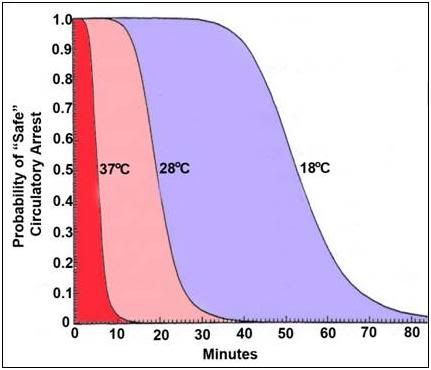

Assuming the patient cooled at the rate that A-1169 did above, then the best that could be expected is that the patient was at ~ 22-24 deg C at 1 hour and 44 min post arrest. Examination of the graph below (Figure 4) shows that the “safe” circulatory arrest times for a “healthy” patient who has had no prior ischemic insult and who is fully oxygenated at various temperatures during cardiac or neurosurgery:

Figure 4: Probable safe circulatory arrest time vs. temperature for humans, as calculated using the Hypothermic Metabolic Index (HMI). [Ungerleider R, Gaynor, JW.: The Boston Circulatory Arrest Study: An analysis. J Thorac Cardiovasc Surg 2004, 127:1256-1261.]

The reason these graphs are of relevance is that in order to do a median sternotomy you must, necessarily, stop CPR. So, yet again, Alcor took a patient with essentially uninterrupted CPS, brought them into the OR and then exposed her 1 hour and 42 minutes of ischemia! A few days before we went to Alcor, I had sent Max a letter pointing out that this had happened yet again, and that Aaron Drake’s report was badly flawed and that it was clear he was wholly inadequately trained to be doing cases unsupervised. I received no reply.

Our visit to Alcor was surreal – absolutely surreal. The first thing Max did when we entered was to show Danila Medvedev and Valerija Pride swatches of wall paper and explain that the office was he was occupying was “not his” and that it was to be redecorated. He then proceeded to do the same with me. Danila and I looked at each other as if to say, “Are you kidding us? Can this even be real?”

An Unkempt Kitchen in a 2-Star Hotel?

When we arrived at Alcor we were informed that a member was in need of Standby and very likely cryopreservation, and shortly after we entered the facility, the Remote Standby Team left with their equipment. I have been at Alcor only at brief intervals over the past 20 years, with the exception a stint for a month or so as subcontractor working for Suspended Animation, Inc. (SA) in 2002. I thus have mental “snapshots” of the state of the facilities separated by considerable intervals of time. This was the most disturbing snapshot I’ve seen so far. The operating room was unkempt. The floors were scuffed, stained, dirty, and had obviously not been waxed in a long time (Figure 5).

Figure 5: Scuffed and dirty floors, dusty shelves and a disorganized appearance are fair descriptors of the Alcor operating room. I wouldn’t consider medical treatment in a facility with this appearance – nor for that matter would I like to dine in a restaurant with a kitchen in such a state. Photo by Stanislaw Lipin; courtesy of KrioRus.

Figure 5: Scuffed and dirty floors, dusty shelves and a disorganized appearance are fair descriptors of the Alcor operating room. I wouldn’t consider medical treatment in a facility with this appearance – nor for that matter would I like to dine in a restaurant with a kitchen in such a state. Photo by Stanislaw Lipin; courtesy of KrioRus.

I inquired when preparation of the operating room would start for the patient who was to be perfused, presumably the next day, and I was told that they were “done.” When we entered the OR I observed tubing strung on the pumps of the heart lung machine console, and had assumed it was training tubing, since some of it was hanging down to the floor in front of the console inside a large, open ZipLoc bag (Figure 5).

Figure 5: Cryoprotective tubing dangling from pump console in a Ziploc bag; proper gas permeable sterilization wrapping (such as Kimlon™) was nowhere in evidence. Photo by Stanislaw Lipin; courtesy of KrioRus.

Figure 5: Cryoprotective tubing dangling from pump console in a Ziploc bag; proper gas permeable sterilization wrapping (such as Kimlon™) was nowhere in evidence. Photo by Stanislaw Lipin; courtesy of KrioRus.

There were discarded tubing (ethylene oxide) sterilization caps lying around, and refuse, some of it apparently in place for some time, such as twist ties and paper backing from discarded sterilization pouches, lying covered in dust on the computer/instrumentation cart adjacent to the pump console (Figures 7 & 8).

Figure 6: Alcor operating room perfusion and data acquisition equipment. The refractometer heads used to continuously acquire cryoprotectant agent concentration to the left of the computer. Photo by Stanislaw Lipin; courtesy of KrioRus.

Figure 6: Alcor operating room perfusion and data acquisition equipment. The refractometer heads used to continuously acquire cryoprotectant agent concentration to the left of the computer. Photo by Stanislaw Lipin; courtesy of KrioRus.

Figure 7: Dust covered lower shelf of the stainless steel data acquisition cart. The piece of sterilization packaging and the twist tie appeared to be covered in a film of dust, as well. Photo by Stanislaw Lipin; courtesy of KrioRus.

Figure 7: Dust covered lower shelf of the stainless steel data acquisition cart. The piece of sterilization packaging and the twist tie appeared to be covered in a film of dust, as well. Photo by Stanislaw Lipin; courtesy of KrioRus.

Figure 8: The recirculating reservoir perched precariously atop the magnetic stirring table used to mix cryoprotectant concentrate into the recirculating perfusate. Photo by Stanislaw Lipin; courtesy of KrioRus.

Figure 8: The recirculating reservoir perched precariously atop the magnetic stirring table used to mix cryoprotectant concentrate into the recirculating perfusate. Photo by Stanislaw Lipin; courtesy of KrioRus.

On the monitor shelf atop the pump console there was a spray bottle that had apparently been labeled “alcohol” (what kind? one wonders) with a Sharpie marker, and a laboratory wash bottle sitting next to it containing a liquid – but with no label (Figure 8).

Figure 9: At top, long view of the neuroperfusion enclosure and at bottom close up showing area of apparent blood contamination. Photo by Stanislaw Lipin; courtesy of KrioRus.

Figure 9: At top, long view of the neuroperfusion enclosure and at bottom close up showing area of apparent blood contamination. Photo by Stanislaw Lipin; courtesy of KrioRus.

Disturbingly, the neuroperfusion enclosure had what appeared to be a residue of dried blood/perfusate in what appeared to be a defect in the adhesive seal where the waste diversion plate is cemented to the side wall of the enclosure (Figure 9). The drain line from the neuroperfusion enclosure (where biohazardous fluid will collect to be disposed of) was sitting unsecured in a ~20 L Costco Kirkland laundry detergent pail (Figure 10).

Figure 10: Costco laundry soap pail containing the unsecured biohazardous waste line from the neuroperfusion enclosure. Photo by Stanislaw Lipin; courtesy of KrioRus.

Figure 10: Costco laundry soap pail containing the unsecured biohazardous waste line from the neuroperfusion enclosure. Photo by Stanislaw Lipin; courtesy of KrioRus.

Figure 11: Alcor Operating room tableaux “fully readied” for a human neuropatient cryoprotective perfusion. Photo by Stanislaw Lipin; courtesy of KrioRus.

The recirculating reservoir was dangerously small making microbubble embolization of the patient during cryoprotective perfusion all but inevitable, since the cold, polymer-rich, viscous perfusate develops stable foam as a consequence of vortex formation and air entrapment from the action of the mixing magnetic stir-bar.

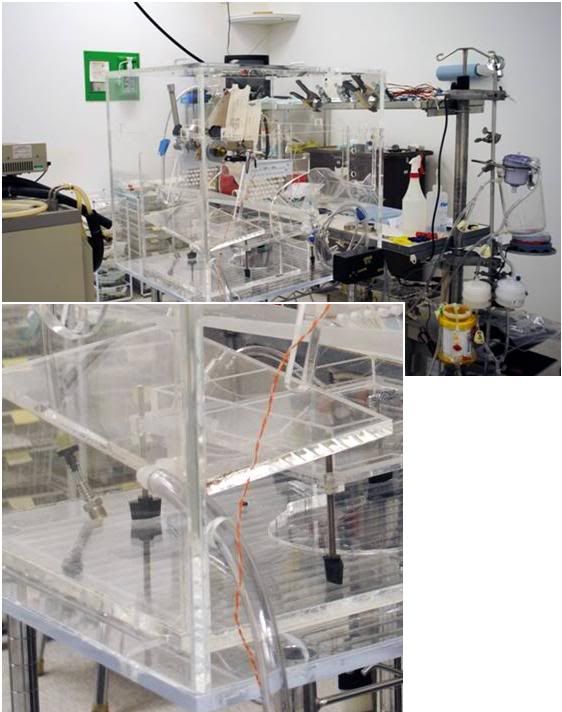

Figure 12: One possible scheme for achieving uniform mixing of cryoprotectant concentrate with the perfusate recirculating through the patient using a static mixer. A concentrate mixing pump continuously removes a large fraction of the recirculating perfusate from a cardiotomy or venous reservoir. This perfusate is then passed through a combination static mixer-heat exchanger where turbulent flow from inertia reversal and radial mixing uniformly blend the added cryoprotectant concentrate with the recirculating perfusate. The static mixer also serves as a heat exchanger. The blended and chilled perfusate then return to the venous reservoir.

Figure 12: One possible scheme for achieving uniform mixing of cryoprotectant concentrate with the perfusate recirculating through the patient using a static mixer. A concentrate mixing pump continuously removes a large fraction of the recirculating perfusate from a cardiotomy or venous reservoir. This perfusate is then passed through a combination static mixer-heat exchanger where turbulent flow from inertia reversal and radial mixing uniformly blend the added cryoprotectant concentrate with the recirculating perfusate. The static mixer also serves as a heat exchanger. The blended and chilled perfusate then return to the venous reservoir.

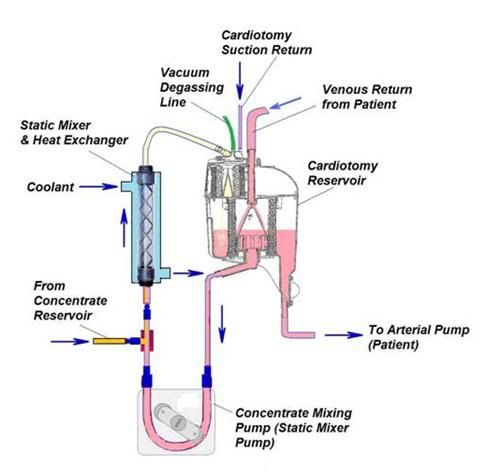

Figure 13: At (A), a typical static mixer array. Static mixers allow thorough mixing of almost any kind of liquid or slurry without the introduction of air or the use of moving parts with the attendant seals. Because static mixers are of necessity a mixing element housed within a tube or cylinder, they make ideal heat exchangers since the fluid flowing inside the mixing tube elements is repeatedly thin-filmed and passed over the tube surface. It is thus possible to very efficiently combine mixing with heat exchange, as can be seen in the combination mixer-heat exchanger seen in B, above.

Figure 13: At (A), a typical static mixer array. Static mixers allow thorough mixing of almost any kind of liquid or slurry without the introduction of air or the use of moving parts with the attendant seals. Because static mixers are of necessity a mixing element housed within a tube or cylinder, they make ideal heat exchangers since the fluid flowing inside the mixing tube elements is repeatedly thin-filmed and passed over the tube surface. It is thus possible to very efficiently combine mixing with heat exchange, as can be seen in the combination mixer-heat exchanger seen in B, above.

This has been a repeated problem in previous cases, and has been the subject of numerous advisory communications between Alcor Director Brian Wowk and me, among others. In fact, despite these repeated warnings (increase depth and volume of the recirculating reservoir, use a floating lid or replace the stir bar assembly with an in-line mixer: Figures 12 & 13), this same phenomenon was noted on during the cryoprotective perfusion of patient A-1097 in January of 2006. A detailed paper documenting this effect and demonstrating a simple way to eliminate it was first published in 1994. ( see: http://www.cryocare.org/index.cgi?subdir=bpi&url=tech5.txt)

I quote from this 1994 paper:

“A consequence of the stirring of the recirculating reservoir by the rapidly spinning magnetic stir bar is the generation of an air vortex in the recirculating perfusate. While this vortex is very effective at both rapidly and completely mixing the concentrate with the perfusate in the recirculating reservoir, it is also very effective at introducing air into the recirculating perfusate as well. At rates of rotation fast enough to achieve good mixing; the bottom of the vortex of air reaches the rapidly rotating stir bar. Air is thus turbulently mixed into the perfusate where it forms bubbles of widely varying size; the smallest of which are very stable. As the concentration of cryoprotectant rises, and the viscosity of the solution correspondingly increases, air bubbles generated by stirring in the recirculating reservoir become more and more stable and begin to saturate the recirculating perfusate creating large amounts of foam.”

And from A-1097’s case report:

“A differential vascular resistance check was done by clamping off and then unclamping the left and right carotid artery respectively. After clamping off the left carotid artery the pressure rose to 72 mm. After clamping off the right carotid artery the pressure rose to 140 mm. At 11:55 foaming was identified in the mixing reservoir, with worse foaming observed at 12:17.”

Figure 14: The recirculating reservoir sitting unsecured atop the mixing stir table. Note that the PVC tubing has not been adanced the requisite 3 barbs over the connector at the bottom (right) of the reservoir and that there is no cable tie in place to prevent accidental disconnection of the tubing. Photo by Stanislaw Lipin; courtesy of KrioRus.

Figure 14: The recirculating reservoir sitting unsecured atop the mixing stir table. Note that the PVC tubing has not been adanced the requisite 3 barbs over the connector at the bottom (right) of the reservoir and that there is no cable tie in place to prevent accidental disconnection of the tubing. Photo by Stanislaw Lipin; courtesy of KrioRus.

It was also sitting akimbo on the magnetic stir table and the connections to and from it, including the critical withdrawal connection at the bottom was neither cable tied, nor pushed over the third barb of the tubing connector at the bottom of the reservoir (these are standard minimum practices for securing tubing against disconnection in extracorporeal medicine).

When I inquired as to how the recirculating reservoir would be secured during perfusion, I was told, “It’ll sit still when it has liquid in it.” If you can look at the picture above and concur with that answer, especially considering that Alcor has a history of pumping this small reservoir dry during perfusion and introducing air in the extracorporeal circuit, then you are a more courageous soul than me. Consider the recommendation made to Alcor by the formal Committee commissioned to evaluate and suggest corrective actions when Alcor’s cryopreservation procedures were found to be severely deficient in 2002:

4.13: Enlarge and alarm the recirculating reservoir.

The recirculating perfusate reservoir ran dry more than once during a recent case. The reservoir should be larger and should have an alarm system that is triggered by a low level of perfusate. At the least one specific person should be assigned the task of monitoring the reservoir.

Cargo Cult Security for Patients?

Then there was the lunacy of the “armored” patient care bay, which Max proudly showed us (Figure 15).

Figure 15: Blast resistant bullet proof window looking into the Alcor patient care bay. The hardened transparent window is backed up with a retractable steel curtain window cover. Photo by Stanislaw Lipin; courtesy of KrioRus.

Figure 15: Blast resistant bullet proof window looking into the Alcor patient care bay. The hardened transparent window is backed up with a retractable steel curtain window cover. Photo by Stanislaw Lipin; courtesy of KrioRus.

I can’t even begin to imagine what all this cost (including reinforcing the perimeter walls). It looks very impressive, and no doubt has considerable “sales” value to the naive, or the foolish.

However, if anyone actually looks past the looking glass (which happens to be blast resistant, in this case) what they will see is the following reality.

Figure 16: View through the window into the patient care bay (PCB). A loose piece of the foil faced cardboard sheeting which covers the plywood roof decking and structural supports that comprise the roof of the PCB are highlighted by the red arrows. Photo by Stanislaw Lipin; courtesy of KrioRus.

Figure 16: View through the window into the patient care bay (PCB). A loose piece of the foil faced cardboard sheeting which covers the plywood roof decking and structural supports that comprise the roof of the PCB are highlighted by the red arrows. Photo by Stanislaw Lipin; courtesy of KrioRus.

The red arrows point to the foil-faced cardboard reflective “insulation” that covers the space between the perlins in the patient care bay. One piece has been left (un-anesthetically) loose adjacent to what appears to be a run of sprinkler pipe. What this told me was that roof of the PCB bay is a paper bag. It almost certainly consists of sheets of plywood or particle board decking covered with a layer of roofing felt, and finally the roofing material itself. Typically, this kind of construction can barely withstand the weight of a 250 lb man. Go up on the roof and walk around yourself, and you’ll immediately get a feel for what I’m talking about – the roof will give and spring back as you walk on it. It is minimally engineered for load bearing, and this fine, and a damn good thing in earthquake country, where tilt-up concrete industrial building construction was first developed.

I can then go to Google Earth and quickly verify that, as of 11-2009, there were no structural or other evident reinforcements to the outside of the roof over the PCB. Maybe there are now (doubtful), but this is very easy to determine, either directly, for the cost of an aerial photograph ($300), or by checking with building and code enforcement to see if any structural permits were issued, and inspections subsequently done. Of course, the easiest way is just to climb up on the building and take a look. The single most important and most elementary security precaution any institution can take to increase the safety of its physical plant is to protect its perimeter. This is why sensitive and vulnerable government and corporate installations are surrounded by fences, patrolled by guards (and often dogs) and where feasible, protected by bollards against bomb bearing vehicular attack. Alcor’s perimeter is unsecured.

Figure 17: Google Earth view of the Alcor facility in 2009 shows no evidence of external (surface) reinforcing and no evidence of razor wire or other perimeter defenses on the roof of Alcor building in general, or the patient care bay in particular.

Figure 17: Google Earth view of the Alcor facility in 2009 shows no evidence of external (surface) reinforcing and no evidence of razor wire or other perimeter defenses on the roof of Alcor building in general, or the patient care bay in particular.

Figure 18: Metal lid covering bigfoot dewar at Alcor. Photo by Stanislaw Lipin; courtesy of KrioRus.

Figure 18: Metal lid covering bigfoot dewar at Alcor. Photo by Stanislaw Lipin; courtesy of KrioRus.

It is also evident that the dewars have no cladding, and that the softest spot is the top of the units where, in order to save both weight and money (again perfectly reasonable), the tops of the foam neck-plugs, as is the industry standard for cryogenic dewars, are fabricated from aluminum, or perhaps a tough plastic, such as ABS. However, in this case, no guessing is required; it is evident that the cover is metal and it is, judging from its thickness, aluminum.

Figure 19: Unsecured facility perimeter and roof of the patient care bay at the Alcor facility in Scottsdale, AZ. The blast and fire resistant neurovaults sit abandoned in the parking lot (red hash mark).

Figure 19: Unsecured facility perimeter and roof of the patient care bay at the Alcor facility in Scottsdale, AZ. The blast and fire resistant neurovaults sit abandoned in the parking lot (red hash mark).

Google even shows me the long abandoned blast resistant neuro-vaults sitting in the parking lot (red hash mark), and confirms that the PCB roof is a standard wooden deck and asphalt configuration which will look structurally just about like this:

Figure 20: Type of roof construction used in the Alcor facility. The large composite wooden beams running from left to right are gluelams – machined pieces of wood glued together under high pressure. The gluelams are the primary load bearing elements of the roof. The single beam structural elements that connect the gluelams are the perlins. The perlins provide most of the structural support for the plywood or chipboard decking of the roof.

Figure 20: Type of roof construction used in the Alcor facility. The large composite wooden beams running from left to right are gluelams – machined pieces of wood glued together under high pressure. The gluelams are the primary load bearing elements of the roof. The single beam structural elements that connect the gluelams are the perlins. The perlins provide most of the structural support for the plywood or chipboard decking of the roof.

What is more, very few, if any people who want to do the patients harm will walk into Alcor on a tour. That’s almost ludicrous, especially when there are much more attractive alternatives. And the most attractive alternative is simply walk up to or drive by the building, and hurl a fragmentation-type explosive device, such as a pipe bomb, on the roof. A more serious and targeted approach would be to climb up on the roof and position heavy explosive charges exactly where they are deemed to do the most damage.

Figure 21: Historically, bollards made of wood, metal or concrete have been used to prevent accidental or deliberate vehicular intrusion into areas where unacceptable damage would result (above, top right). More recently, concrete barriers such as the ones seen at top left have been used for this purpose. (Photos by Mike Darwin.) The use of concrete barriers, or K rails is, however, not only unaesthetic, it does not provide protection against the intrusion of armed pedestrians, or 2-wheel vehicles such as bicycles and motorcycles. An effective alternative is the use of high impact and climb-over resistant fencing such as Ameristar Fence Products, Inc., (Tulsa, OK), Impasse™ high-security fencing system. With the company’s integrated cabling system, this product provides anti-ram defense against forced entry and ballistic attack, and is able to stop one 15,000 lb vehicle traveling 40 mph. This product meets Department of State’s K8/L1 and K8/L2 ratings.

So, in effect, the Alcor PCB is the equivalent of a Bugatti Verynon Sports car, which has excellent door locks and a great alarm system – all of which are of little utility in the event you leave the roof off!

Figure 22: The Bugatti Verynon features an excellent alarm system and a sporty, removable roof. The value of the alarm system is considerably diminished if the car is left parked with the roof off.

Figure 22: The Bugatti Verynon features an excellent alarm system and a sporty, removable roof. The value of the alarm system is considerably diminished if the car is left parked with the roof off.

It is, of course, possible to really protect the patients against these kinds of threats, as well as radiation damage by placing the patient dewars in below ground silos as seen in Figure 23. But it isn’t pretty, although I guarantee you that this, or some variation of it, will be a whole lot more effective and less costly.

Figure 23: Truly effective blast, earthquake and radiation protection were achieved by CryoSpan in the late 1990s by the expedient of constructing in-ground steel reinforced concrete silos. At top, engineer Mark Connaughton works on the wooden support framing used to maintain the shape of the mold prior to pouring the concrete. While not offering “sexy” photo opportunities, such silos provide robust and affordable protection to cryonics patients. Photos by Charles Platt.

Figure 23: Truly effective blast, earthquake and radiation protection were achieved by CryoSpan in the late 1990s by the expedient of constructing in-ground steel reinforced concrete silos. At top, engineer Mark Connaughton works on the wooden support framing used to maintain the shape of the mold prior to pouring the concrete. While not offering “sexy” photo opportunities, such silos provide robust and affordable protection to cryonics patients. Photos by Charles Platt.

Subsequently, Max and I corresponded about these issues until it became clear that he was becoming angry with me. He denied that there was any current wastefulness at Alcor (including their 10 paid employees), challenging me to come up with line item examples; except, of course, I couldn’t do this because Alcor has published no financial reports in four years. In fact, such reports don’t exist (not yet, anyway). He did not respond to my query about why the MARC is no longer in use and lies covered in dust (not even tarped) and laden with ‘junk’ in the ambulance bay; it has been replaced by a waist high PIB fabricated from stainless steel. All of which begs the question of why a complex and costly technological platform, in the form of a mobile operating room was developed, if it isn’t going to be used for extracorporeal support?

Our correspondence pretty much ended with me telling him, “You may not agree with what my vision for Alcor was (in 1987) at this point in time, but the really unfortunate thing, for all involved, is that you probably have no idea what it was, nor why I am unhappy at the waste of millions of dollars of contributed member money[1] in the intervening decades. And Max, those millions were wasted.”

Every “criticism” I made he took as a personal challenge to his competence. Danila described it aptly as, “Horrible.” It now seems clear to me that nothing I can do from behind the scenes will change Alcor. I’ve been working quietly for over a decade now, and things just keep getting worse. I had planned for this contingency, and now I think it is time to proceed in creating an alternative organization and to providing some of the nocioception that Alcor has been spared these past 20 years. I like Max a great deal – we have been good friends for over 20 years.But this is business, serious life or death business.

I have been through at least 4 iterations of what amounted to effectively rebooting, or trying to be reboot cryonics organizations. It takes a long time to do that: ~5 years just to get some equilibrium and the core resources in place. Surprisingly, even throwing vast amounts of money into such efforts does nothing to accelerate the pace, and may even slow it. I’m old, and I am sickened at the thought of having to go through this exercise, even as a participant, let alone as a leader, yet again. Having said that, it is becoming clear with each passing year that this kind of effort was probably inevitable given our nearly complete lack of understanding of what was (and arguably still is) really required to do cryonics in a sustainable fashion. Certainly, there is no escape from this in most other endeavors – and especially not in fundamentally new ones. I rarely meet innovators or entrepreneurs on the “cutting edge” (an expression I loathe) who don’t have sad tales to tell about how many corporate entities they created and cycled through before they found a stable and durable platform (if they ever succeeded in doing so at all).

As to Alcor’s status and prospects, I don’t think Alcor is likely to fail in any kind of immediate or catastrophic way. It’s current and past deficiencies are primarily of a kind that, given cryonics’ fundamental lack of normal market feedback, will not be evident to cryonicists, let alone to the public, even if pointed out to them. The legacy of the Cryonics Society of California (CSC) is proof of that reality. So, that’s not what I’m saying.

The Stench of Impending Failure?

What I am saying is that there are certain infallible signs that an enterprise is in deep trouble, and while perhaps not in immediate danger of going under, is only going to continue to exist under highly favorable conditions. I’ll be quite specific in a moment, but I want to a spend few moments more on what is the really the more important point I have to make.

I’ve traveled the world and visited just about every kind of enterprise imaginable. Whether it is a restaurant Florence, a medical clinic in Hyderabad, or an ICU in Mumbai or Moscow, there is often this unmistakable gestalt (stench) of a profoundly dysfunctional business which is evident within minutes of being on the premises. Please note that I am not saying that all failing enterprises exhibit this aura, because I’m sure they don’t. Enron probably seemed in fine fettle until just before the end. But I am saying that when that ambience is present, the enterprise is in extremis. Under normal market conditions that would mean that you could reasonably (soon) expect the doors to be shuttered (or the floor to be removed, in the Middle East). The exceptions are small town businesses that constitute micro-monopolies, government operated facilities in the undeveloped world, and occasionally, religious orders or other institutions in terminal decline, but who have a trust fund or other stipend to sustain them.

Cryonics: A Product or an Unproven Experimental Procedure?

While in many important ways Alcor is the descendant of Cryonics Society of New York (CSNY) and the no-nonsense, tell like it is approach to cryonics of Curtis Henderson, this is not by any means the full picture. CSNY had perhaps half the paradigm right. The other half that came to constitute the “mature” Alcor approach of the 1980s was pioneered by Fred and Linda Chamberlain, and was one of the Alcor assets already in place, if dormant, when IABS and I arrived on the scene in 1981. That approach was a clear acknowledgement and understanding that cryonics was an experimental procedure, that Alcor was a mutual aid organization, and that recruiting members who were also experimental subjects, was not the same as selling cryonics to customers.

There was, in fact, a strong aversion to marketing cryonics as an ordinary product, or even as a “regular” medical treatment. A consequence of this attitude was that everyone who interfaced with the public, until shortly before I left, had an almost fanatical attitude about how signing up should be communicated to the member. The interesting, and indeed remarkable thing about this is that I do not ever recall doing any training or any scripting of how to handle callers who were prospective members, or who were gathering information for same. It was just something that was “organic” and a part of Alcor’s small, but very well defined corporate culture at that time.

A corollary or a logical extension of this “first contact” strategy was that we spent a lot of time and expended a lot of effort not only continuously educating already signed up members, but actively ensuring that their informed consent was maintained over time. The Cryonics Institute (CI) never had that paradigm and Alcor lost it, and as result, members got translated into customers. I believe this is a critical failure mode for a cryonics organization – any cryonics organization – because whatever else cryonics patients are, they are not customers, and neither are members customers before they become patients. The definition of customer is innocuous enough: A party that receives or consumes products (goods or services) and has the ability to choose between different products and suppliers. Superficially it would seem to fit the bill for cryonics. Unfortunately, it is not what is present in that definition that is problematic, it is what is missing.

By contrast, consider the definition of the word patient:

1. Bearing or enduring pain, difficulty, provocation, or annoyance with calmness.

2. Marked by or exhibiting calm endurance of pain, difficulty, provocation, or annoyance.

3. Tolerant; understanding: an unfailingly patient leader and guide.

4. Persevering; constant: With patient industry, she revived the failing business and made it thrive.

5. Capable of calmly awaiting an outcome or result; not hasty or impulsive.

6. Capable of bearing or enduring pain, difficulty, provocation, or annoyance: “My uncle Toby was a man patient of injuries” (Laurence Sterne).

noun:

1. One who receives medical attention, care, or treatment.

2. Linguistics A noun or noun phrase identifying one that is acted upon or undergoes an action. Also called goal.

3. Archaic One who suffers.

The core of the definition of patient, which was the basis of the adoption of the word in medicine, is “one who demonstrates calm endurance of pain, difficulty, provocation, or annoyance.” Anyone involved in cryonics for very long will quickly come to know, viscerally, which of these terms best applies.

No law yet prohibits marketing cryonics as a consumer product, though some do exist prohibiting its marketing at all. One of the few advantages to age (especially if accompanied by global travel) is that you get to see how diverse societies handle certain classes of problematic services or undertakings – ones that are destabilizing to the social matrix, or which carry a high potential for fraud or exploitation of the individual, especially vulnerable individuals. While there is considerable variation in the details, the general approaches used are remarkably similar within societies that share the same basic values. So, while there is the sale of vital organs in places like India (something that is fast being regionally legislated against), you see either a complete absence of this practice, or the same limited workarounds, in virtually all of the West and Near East. As a relevant aside, it was fascinating to watch the arc of gambling in the Russian Republic, which went from ubiquitous, to exactly where it was in the US 20 years ago; mostly prohibited, except in special zones that are problematic to gain access to and which focus the predation on the wealthy (there is essentially no middle class in Russia). This change occurred in ~2 years!

The point here is that any enterprise operating as a low temperature mausoleum with the added benefit of prospective resurrection, and doing so on a razor thin margin of costs, is very likely headed for trouble. And precisely because they are primarily a customer service organization engaged in selling only the first half of the “product” (i.e., cryopreservation and storage) they will simply not “get it” when the second half of the product is neglected or threatened (i.e., stewardship and resuscitation). Reanimation is a matter for our friends in the future, and an inevitable consequence of this is that day-to-day things that impact its likelihood today are likely to be viewed as of little or no consequence. Indeed, they are not even likely to be perceived at all. I gained enormous respect for Melody Maxim’s ability to inflict harm[2] when she correctly perceived that CI (and thus ACS) had surrendered all practical control over their patients to the Michigan Cemetery Board by the “simple” act of submitting to state regulation.

That and (many) other insights aside, the one of most relevance to this discussion happened when I was dozing on the couch in the reception area (the Russians proved equally exhausting and rewarding to travel with). As I went in and out of consciousness, I could hear the phone being answered at Alcor, and the first thing that caught my attention and increased my level of alertness for the next call was that most of the incoming calls were from people who were apparently inquiring about cryonics services. Maybe I was just there on an unusually busy day, but I heard several calls – more than two and less than five, in the hour plus interval I intermittently slumbered. The side of the calls I could hear went very much like this: “Alcor Foundation,” silence “yes we offer that.” Silence “Are you interested in the whole body or the neuro. The whole body is $200,000 and the neuro is $80,000. Silence. “The whole body is your entire body, and the neuro is just your head.” Silence. “We’re located in the Scottsdale Airpark, which is just outside of Phoenix, and if you would like to arrange a tour we would be glad to show you through our facilities.” Silence. “Most people pay for it with life insurance, and if you like, I can refer to our life insurance representative.” Silence. “Well, if you are ever in the Phoenix metro area, please consider making arrangements to see our facilities.” Silence. “Thank you.”

As I sat there, semiconscious, I had two recurring thoughts that played tag with each other in my fogged brain:

1) Are you interested in the whole body or the neuro? And would like fries and a coke with that?

2) Please, please, let me be dreaming.

I told Max about this and he expressed some concern, informed me that the person handling the inquiries was not a signed up cryonicist, but was nevertheless “a very good employee and very loyal to cryonics.” He told me he would look into the matter (after all, I was dozing) and that he would see about scripting such encounters should it prove necessary. As I sit here in Dulwhich, London, and watch the heavy gray North Sea clouds parade across the fast darkening sky whilst spitting rain, I shudder at the thought of the theatre d’absurb that scipt will be written and performed in.

There is a large and very material difference between continuing to advertise for and accept guests if you are a hotel with fire code deficiencies (that is aware of this and working to fix them), versus being a hotel that is actually on fire. It is a peculiarity of certain kinds of institutions that they will, in fact, continue to solicit and escort new guests to their rooms, even as fire from an already engulfed kitchen, barrels up stairwells with no fire doors. Such behavior happens not infrequently in enterprises where there is any material separation of “operations” from “feedback” (as any number of the recent real estate and financial debacles demonstrate).

What Next?

In my opinion, Alcor is a hotel on fire, already seriously engulfed, and with no plan of any kind, let alone a detailed one, for extinguishing the blaze and rebuilding the infrastructure. A better analogy might be a sinking ship – because the passengers can’t just stroll over to the venue across the street – they are stuck where they are. I expect that most reading this will tell me that this is not so, that I am mistaken, or that I am excessively pessimistic, or even malicious…and that’s fine. I’m not about insisting that everyone share my opinions. I may in fact be wrong. However, what I am not wrong about is that Alcor is profoundly dysfunctional, and that many discrete and general problems can be objectively identified that will likely lead to its eventual failure or replacement. I can also say with a high degree of confidence that those members who are not customers, are either aware of this situation, or are very dissatisfied with Alcor’s performance (particularly its wastefulness and low quality of service).

Opinions aside, what I believe is necessary, which in this case is both an opinion and a fact, is some sort of detailed, credible acknowledgement and understanding of the problems, coupled with a realistic plan for fixing them. Preferably a plan that does not involve asking members for yet more money to hire yet more staff.

Footnotes

[1] Ironically, approximately $4 million of that money came from the Dick Jones estate; a bequest which I was instrumental in directing to the operating fund. For this advice I feel a great deal of humiliation and regret and will sincerely apologize to Dick if I ever get the chance.

[2] And conversely to do good by pointing out soft spots and likely failure modes.

A Visit to Alcor

“Are you interested in the whole body or the neuro? And would like fries and a coke with that?”

By Mike Darwin

A short while ago, I hosted 3 visitors from the Russian cryonics organization KrioRus. During my visit with them in Moscow two and a half years previously, I had exhorted them to visit the US and see first-hand any hub of cryonics activity there, so that that they could see and learn for themselves what cryonics was really like, and how it was actually being pursued in the US. When I wrote to Alcor President and CEO Max More to try and schedule a visit on short notice, I jokingly included the aside that if I was not permitted to be on premises, I would go elsewhere… It was intended to be a humorous reference to a time in the not so distant past when I was not allowed into Alcor because my homosexuality was “unacceptable” to a former Alcor President (apparently being incompatible with his religious beliefs).

To my considerable surprise, Max took this remark seriously, and polled the Alcor Board on the matter. Surprise was replaced with shock when I subsequently learned that Alcor Director Saul Kent had expressed concerns that my visit to Alcor accompanying the Russians would be used as tool to “attack Alcor.” I still find this shocking, but depending upon how you define attack, maybe Saul was closer to the truth than I imagined possible. I’ve since been told that apparently there were speculations that “touring Russians” might be just an excuse of some kind to gain entry to Alcor.[1] Why this should be necessary is still a mystery to me, since as far as I knew I could visit by making by an appointment, presumably like anyone else.

Figure 1: The Alcor Mobile Advanced Rescue Cart (MARC), a portable extracorporeal support platform.

I saw quite a few unexpected things at Alcor, such as that the MARC is no longer in use and lies covered in dust (not even tarped) and laden with ‘junk’ in the ambulance bay; it has been replaced by waist high PIB fabricated from stainless steel. All of which begs the point of why a hugely complex and costly technological platform, in the form of a mobile operating room was developed, if it isn’t going to be used for extracorporeal support?

Figure 2: Left to right, Danila, Medvedev, President of the Russian Transhumanist Association, Max More, Ph.D., President and CEO of Alcor and Valerija Pride, President of KrioRus.

Shortly after he took office, I sent Max the 100+ plus page “Report of the Committee to Evaluate Alcor Procedures” which was presented to the Alcor Board of Directors on 04 April, 2002. This report came about because Saul Kent invited me over to view videotapes of two Alcor cases which troubled him – but he couldn’t quite put his finger on why this was so. What I saw shocked and disguste. Patients were being stabilized at a nearby hospice, transported to Alcor (~20 min away) and then CPS was discontinued, the patients were placed on the OR table and, without any ice on their heads, they were allowed to sit there at a temperatures a little below normal body temperature for 1 to 1.5 hours, while burr holes were drilled and the neck vessels were cannulated. Distilled water was being used to irrigate the brain and burr holes were done with a wood burr and electric drill with no cooling of the bone under the burr – smoke could be seen coming from the burr wound! Since the patient had no circulation to provide blood to carry away the enormous heat generated by the action of the burr on the bone, the temperature of the underlying bone must have been high enough to literally cook an egg.

In one case, a patient’s head was cut off in the field and, because they had failed to use a rectal plug, he had defecated in the PIB. The result was that feces had contaminated the neck wound, and Alcor personnel were seen pouring saline over the stump of the neck whilst holding the patient’s severed head over a bucket trying to wash the fecal matter off the stump! These are just a few of the grotesque problems I saw.

As a consequence, a “blue ribbon” Committee was put together to comprehensively review Alcor patient videos and records, and to make a field inspection of the Alcor facility. This Committee produced a comprehensive report and presented it to the Alcor Board. Max More knew nothing of this until I sent him a copy after he was President for about 1.5 months. A short while later, Alcor published the first detailed case report since the A-1169 case report was published in 2006. A careful reading of this case report which is available at http://www.alcor.org/Library/pdfs/casereportA2435.pdf and discloses that there is something terribly wrong that happens during this case, but unless you really understand cryonics as medicine, you are not likely to see it. The patient was pronounced at 6:58 PM and was transported to Alcor packed in ice while receiving CPS with the LUCAS. At ~ 8:42 PM, 1 hour and 42 minutes later, a median sternotomy is begun (excerpt from the case report, emphasis mine):

Continuation of CPS

Move to surgical table

7. Surgical Procedures

Manual CPS was continued on the patient while fresh ice was brought in from Alcor’s ice machine. The existing ice was removed from on top of the patient and she was pulled out of the ice bath and placed on the OR surgical table at 8:11 pm.

Testing of the sternal saw prior to the surgery revealed that the flexible shaft had frozen up. The problem was handed to Richard to deal with, and he had it unfrozen in a few minutes. The shaft was subsequently disassembled and lubricated. 15

The patient’s head was shaved to prep for the burr holes to be drilled. These are used to monitor the temperature of the patient’s brain as well as a way to visually watch for swelling. While the burr holes were being drilled using a craniotome perforator, Aaron prepped the patient’s sternum with Betadine, an antiseptic agent used topically to destroy microbes. Dr. McEachern cleaned each of the burr holes as they were completed. At 8:42 PM, she stood on a step stool to gain a higher position above the patient in order to perform a median sternotomy. This is a procedure in which a vertical inline incision is made along the sternum, after which the sternum itself is divided to provide access to the heart for cannulation. Dr. McEachern cut through the skin of the chest with a scalpel. The guide of the saw blade was placed below the sternum. Richard operated the foot pedal on the floor as she guided the saw up the sternum. She talked through the procedure, step by step, to Aaron so he could gain additional training in its operation and application. After the sternum separation was completed, the chest was opened with Finochietto spreaders and the pericardial sac was exposed. Access to the heart was accomplished by cutting through the pericardium.

Dr. McEachern performed an arterial cannulation of the heart by sewing a purse-string suture into the wall of the aortic arch, puncturing the vessel within the purse-string, and advancing and securing the catheter. She then repeated this process for venous cannulation of the heart, going into the right atrium and advancing the cannula into the inferior vena cava. This process took approximately one hour and was completed at 9:48 PM. A thermocouple was placed under the dura through the burr hole at 3.0 hours post-arrest. Brain temperatures were taken under the dura and beneath the brain (nasopharyngeal).

Now the washout could begin. This process is used to replace the patient’s blood with cryoprotectant. The extracorporeal perfusion circuit had been primed with B1 base perfusate solution prior to the surgery and was being circulated through the bypass loop. When cannulation was complete, the circulation was transferred from the bypass loop into the cannulas. The circuit was switched from closed to open circulation and the blood was washed out of the patient’s vascular system, the visual blood concentration going from opaque to light pink.

The graph of below shows a typical patient’s cooling rate in the PIB:

Figure 3: The red-boxed areas of the two cooling curves above show the likely temperature range a patient would have cooled to during 1 hour and 44 minutes of closed chest cardiopulmonary supported external cooling using ■ ice bags or □ Portable Ice Bath (PIB) cooling.

Assuming the patient cooled at the rate that A-1169 did above, then the best that could be expected is that the patient was at ~ 22-24 deg C at 1 hour and 44 min post arrest. If you look at the graph below you see the “safe” circulatory arrest times for a “healthy” patient who has had no prior ischemic insult and who is fully oxygenated at various temperatures during cardiac or neurosurgery:

Figure 4: Probable safe circulatory arrest time vs. temperature for humans, as calculated using the Hypothermic Metabolic Index (HMI).

The reason these graphs are of relevance is that in order to do a median sternotomy you must, necessarily, stop CPR. So, yet again, Alcor took a patient with essentially uninterrupted CPS, brought them into the OR and then exposed her 1 hour and 42 minutes of ischemia! A few days before we went to Alcor, I had sent Max a letter pointing out that this had happened yet again, and that Aaron Drake’s report was badly flawed and that it was clear he was wholly inadequately trained to be doing cases unsupervised. I received no reply. Our visit to Alcor was surreal – absolutely surreal. The first thing Max did when we entered was to show Danila Medvedev and Valerija Pride swatches of wall paper and explain that the office was he was occupying was “not his” and that it was to be redecorated. He then proceeded to do the same with me. Danila and I looked at each other as if to say, “Are you kidding us? Can this even be real?”

When we arrived at Alcor we were informed that member was in need of Standby and very likely cryopreservation, and shortly after we entered the facility, the Remote Standby Team left with their equipment. I have been at Alcor only at brief intervals over the past 20 years, with the exception a stint for a month or so as subcontractor working for Suspended Animation, Inc. (SA) in 2002. I thus have mental “snapshots” of the state of the facilities separated by considerable intervals of time. This was the most disturbing snapshot I’ve seen so far. The operating room was unkempt. The floors were scuffed, stained, dirty, and had obviously not been waxed in a long time.

Figure 5: Scuffed and dirty floors, dusty shelves and a disorganized appearance are fair descriptors of the Alcor operating room. I wouldn’t consider medical treatment in a facility with this appearance – nor for that matter would I like to dine in a restaurant with a kitchen in such a state.

I inquired when preparation of the operating room would start for the patient who was to be perfused, presumably the next day, and I was told that they were “done.” When we entered the OR I observed tubing strung on the pumps of the heat lung machine console, and had assumed it was training tubing, since some of it was hanging down to the floor in front of the console inside a large, open ZipLoc bag.

Figure 5: Cryoprotective tubing dangling from pump console in a Ziploc bag; proper gas permeable sterilization wrapping (such as Kimlon™) was nowhere in evidence.

There were discarded tubing (ethylene oxide) sterilization caps lying around, and refuse, some of it apparently in place for some time, such as twist ties and paper backing from discarded sterilization pouches, lying covered in dust on the computer/instrumentation cart adjacent to the pump console.

Figure 6: Alcor operating room perfusion and data acquisition equipment. The refractometer heads used to continuously acquire cryoprotectant agent concentration to the left of the computer.

Figure 7: Dust covered lower shelf of the stainless steel data acquisition cart. The piece of sterilization packaging and the twist tie appeared to be covered in a film of dust, as well.

Figure 8: The recirculating reservoir perched precariously atop the magnetic stirring table used to mix cryoprotectant concentrate into the recirculating perfusate.

On the monitor shelf atop the pump console there was a spray bottle that had apparently been labeled “alcohol” (what kind? one wonders) with a Sharpie marker, and a laboratory wash bottle sitting next to it containing a liquid – but with no label.

Figure 9: At top, long view of the neuroperfusion enclosure and at bottom close up showing area of apparent blood contamination.

Disturbingly, the neuroperfusion enclosure had what appeared to be a residue of dried blood/perfusate in what appeared a defect in the adhesive seal where the waste diversion plate is cemented to the side wall of the enclosure. The drain line from the neuroperfusion enclosure (where biohazardous fluid will collect to be disposed of) was sitting unsecured in a ~20 L Costco Kirkland laundry detergent pail.

Figure 10: Costco laundry soap pail containing the unsecured biohazardous waste line from the neuroperfusion enclosure.

Figure 11: Alcor Operating room tableaux “fully readied” for a human neuropatient cryoprotective perfusion.

The recirculating reservoir was dangerously small making microbubble embolization of the patient during cryoprotective perfusion all but inevitable, since the cold, polymer-rich, viscous perfusate develops stable foam as a consequence of vortex formation and air entrapment from the action of the mixing magnetic stir-bar.

Figure 12: One possible scheme for achieving uniform mixing of cryoprotectant concentrate with the perfusate recirculating through the patient using a static mixer. A concentrate mixing pump continuously removes a large fraction of the recirculating perfusate from a cardiotomy or venous reservoir. This perfusate is then passed through a combination static mixer-heat exchanger where turbulent flow from inertia reversal and radial mixing uniformly blend the added cryoprotectant concentrate with the recirculating perfusate. The static mixer also serves as a heat exchanger. The blended and chilled perfusate then return to the venous reservoir.

Figure 13: At (A), a typical static mixer array. Static mixers allow thorough mixing of almost any kind of liquid or slurry without the introduction of air or the use of moving parts with the attendant seals. Because static mixers are of necessity a mixing element housed within a tube or cylinder, they make ideal heat exchangers since the fluid flowing inside the mixing tube elements is repeatedly thin-filmed and passed over the tube surface. It is thus possible to very efficiently combine mixing with heat exchange, as can be seen in the combination mixer-heat exchanger seen in B, above.

This has been a repeated problem in previous cases, and has been the subject of numerous advisory communications between Alcor Director Brian Wowk and me, among others. In fact, despite these repeated warnings (increase depth and volume of the recirculating reservoir, use a floating lid or replace the stir bar assembly with an in-line mixer), this same phenomenon was noted on during the cryoprotective perfusion of patient A-1097 in January of 2006. A detailed paper documenting this effect and demonstrating a simple way to eliminate it was first published in 1994. ( see: http://www.cryocare.org/index.cgi?subdir=bpi&url=tech5.txt)

I quote from our 1994 paper:

“A consequence of the stirring of the recirculating reservoir by the rapidly spinning magnetic stir bar is the generation of an air vortex in the recirculating perfusate. While this vortex is very effective at both rapidly and completely mixing the concentrate with the perfusate in the recirculating reservoir, it is also very effective at introducing air into the recirculating perfusate as well. At rates of rotation fast enough to achieve good mixing; the bottom of the vortex of air reaches the rapidly rotating stir bar. Air is thus turbulently mixed into the perfusate where it forms bubbles of widely varying size; the smallest of which are very stable. As the concentration of cryoprotectant rises, and the viscosity of the solution correspondingly increases, air bubbles generated by stirring in the recirculating reservoir become more and more stable and begin to saturate the recirculating perfusate creating large amounts of foam.”

And from A-1097’s case report:

“A differential vascular resistance check was done by clamping off and then unclamping the left and right carotid artery respectively. After clamping off the left carotid artery the pressure rose to 72 mm. After clamping off the right carotid artery the pressure rose to 140 mm. At 11:55 foaming was identified in the mixing reservoir, with worse foaming observed at 12:17.”

Figure 14: The recirculating reservoir sitting unsecured atop the mixing stir table. Note that the PVC tubing has not been advanced the requisite 3 barbs over the connector at the bottom (right) of the reservoir and that there is no cable tie in place to prevent accidental disconnection of the tubing.

It was also sitting akimbo on the magnetic stir table and the connections to and from it, including the critical withdrawal connection at the bottom was neither cable tied, nor pushed over the third barb of the tubing connector at the bottom of the reservoir (these are standard minimum practices for securing tubing against disconnection in extracorporeal medicine).

When I inquired as to how the recirculating reservoir would be secured during perfusion, I was told, “It’ll sit still when it has liquid in it.” If you can look at the picture above and concur with that answer, especially considering that Alcor has a history of pumping this small reservoir dry during perfusion and introducing air in the extracorporeal circuit, then you are more courageous soul than me. Consider the recommendation made to Alcor by a formal Committee commissioned to evaluate and suggest corrective actions when Alcor’s cryopreservation procedures were found to be severely deficient in 2002:

4.13: Enlarge and alarm the recirculating reservoir.

The recirculating perfusate reservoir ran dry more than once during a recent case. The reservoir should be larger and should have an alarm system that is triggered by a low level of perfusate. At the least one specific person should be assigned the task of monitoring the reservoir.

Then there was the lunacy of the “armored” patient care bay, which Max proudly showed off.:

Figure 15: Blast resistant bullet proof window looking into the Alcor patient care bay. The hardened transparent window is backed up with a retractable steel curtain window cover.

I can’t even begin to imagine what all this cost (including reinforcing the perimeter walls). It looks very impressive, and no doubt has considerable “sales” value to the naive, or the foolish.

However, if anyone actually looks past the looking glass (which happens to be blast resistant, in this case) what they will see is the following reality.

Figure 16: View through the window into the patient care bay (PCB). A loose piece of the foil faced cardboard sheeting which covers the plywood roof decking and structural supports that comprise the roof of the PCB are highlighted by the red arrows.

The red arrows point to the foil-faced cardboard reflective “insulation” that covers the space between the perlins in the patient care bay. One piece has been left (un-anesthetically) loose adjacent to what appears to a run of sprinkler pipe. What this told me was that roof of the PCB bay is a paper bag. It almost certainly consists of a sheet of plywood or particle board decking covered with a layer of roofing felt, and finally the roofing material itself. Typically, this kind of construction can barely withstand the weight of a 250 lb man. Go up on the roof and walk around yourself, and you’ll immediately get a feel for what I’m talking about – the roof will give and spring back as you walk on it. It is minimally engineered for load bearing, and this fine, and a damn good thing in earthquake country, where tilt-up construction was first developed.

I can then go to Google Earth and quickly verify that, as of 11-2009, there were no structural or other evident reinforcements to the outside of the roof over the PCB. Maybe there are now (doubtful), but this is very easy to determine, either directly, for the cost of an aerial photograph ($300), or by checking with building and code enforcement to see if any structural permits were issued, and inspections subsequently done. Of course, the easiest way is just to climb up on the building and take a look. The single most important and most elementary security precaution any institution can take to increase the safety of its physical plant is to protect its perimeter. This why sensitive and vulnerable government and corporate installations are surrounded by fences, patrolled by guards (and often dogs) and where feasible, protected by bollards against bomb bearing vehicular attack. Alcor’s perimeter is unsecured.

Figure 17: Google Earth view of the Alcor facility in 2009 shows no evidence of external (surface) reinforcing and no evidence of razor wire or other perimeter defenses on the roof of Alcor building in general, or the patient care bay in particular.

Figure 18: Metal lid covering bigfoot dewar at Alcor.

It is also evident that the dewars have no cladding, and that the softest spot is the top of the units where, in order to save both weight and money (again perfectly reasonable), the tops of the foam neck-plugs, as is the industry standard for cryogenic dewars, are fabricated from aluminum, or perhaps a tough plastic, such as ABS. However, in this case, no guessing is required; it is evident that the cover is metal and it judging from its thickness, aluminum.

Figure 19: Unsecured facility perimeter and roof of the patient care bay at the Alcor facility in Scottsdale, AZ. The blast and fire resistant neurovaults sit abandoned in the parking lot (red hash mark).

Google even shows me the neuro-vaults sitting in the parking lot (red hash mark), and confirms that the PCB roof is a standard wooden deck and asphalt configuration which will look structurally just about like this:

Figure 20: Type of roof construction used in the Alcor facility. The large composite wooden beams running from left to right are gluelams – machined pieces of wood glued together under high pressure. The gluelams are the primary load bearing elements of the roof. The single beam structural elements that connect the gluelams are the perlins. The perlins provide most of the structural support for the plywood or chipboard decking of the roof.

What is more, very few, if any people who want to do the patients harm will walk into Alcor on a tour. That’s almost ludicrous, especially when there are much more attractive alternatives. And the most attractive alternative is simply walk up to or drive by the building, and hurl a fragmentation-type explosive device, such as a pipe bomb, on the roof. A more serious and targeted approach would be to climb up on the roof and position a heavy explosive charge exactly where they are deemed to do the most damage.

So, in effect, the Alcor PCB is the equivalent of a Bugatti Verynon Sports car, which has excellent door locks and a great alarm system – all of which are of little utility in the event you leave the roof off!

Figure 21: The Bugatti Verynon features an excellent alarm system and a sporty, removable roof. The value of the alarm system is considerably diminished if the car is left parked with the roof off.

It is, of course, possible to really protect the patients against these kinds of threats, as well as radiation damage. But it isn’t pretty, although I guarantee you that this, or some variation of it, will be a whole lot more effective and less costly.

Figure 22: Truly effective blast, earthquake and radiation protection were achieved by CryoSpan in the late 1990s by the expedient of constructing in-ground steel reinforced concrete silos. At top, engineer Mark Connaughton works on the wooden support framing used to maintain the shape of the mold prior to pouring the concrete. While not offering “sexy” photo opportunities, such silos provide robust and affordable protection to cryonics patients.

Subsequently, Max and I corresponded about these issues until it became clear that he was becoming angry with me. He denied that there was any current wastefulness at Alcor (including their 10 paid employees), challenging me to come up with line item examples; except, of course I couldn’t do this because Alcor has published no financial reports in four years. In fact, they don’t exist (not yet, anyway). He did not respond to my query about why the MARC is no longer in use and lies covered in dust (not even tarped) and laden with ‘junk’ in the ambulance bay; it has been replaced by a waist high PIB fabricated from stainless steel. All of which begs the question of why a complex and costly technological platform, in the form of a mobile operating room was developed, if it isn’t going to be used for extracorporeal support?

Our correspondence pretty much ended with me telling him, “You may not agree with what my vision for Alcor was (in 1987) at this point in time, but the really unfortunate thing, for all involved, is that you probably have no idea what it was, nor why I am unhappy at the waste of millions of dollars of contributed member money[2] in the intervening decades. And Max, those millions were wasted.”

Every “criticism” I made he took as a personal challenge to his competence. Danila described it aptly as, “Horrible.” It now seems clear to me that nothing I can do from behind the scenes will change Alcor. I’ve been working quietly for over a decade now, and things just keep getting worse. I had planned for this contingency, and now I think it is time to proceed in creating an alternative organization and to providing some of the nocioception that Alcor has been spared these past 20 years. I like a Max a great deal – we have been good friends for over 20 years.

I have been through at least 4 iterations of what amounted to effectively rebooting, or trying to be reboot cryonics organizations. It takes a long time to do that: ~5 years just to get some equilibrium and the basic resources in place. Surprisingly, even throwing vast amounts of money into such efforts does nothing to accelerate the pace, and may even slow it. I’m old, and I am sickened at the thought of having to go through this exercise, even as a participant, let alone a leader, yet again. Having said that, it is becoming clear with each passing year that this kind of effort was probably inevitable given our nearly complete lack of understanding of what was (and arguably still is) really required to do cryonics in a sustainable fashion. Certainly, there is no escape from this in most other endeavors – and especially not in fundamentally new ones. I rarely meet innovators or entrepreneurs on the “cutting edge” (an expression I loathe) who don’t have sad tales to tell about how many corporate entities they created and cycled through, before they found a stable and durable platform (if they ever succeeded in doing so at all).

As to Alcor’s status and prospects, I don’t think Alcor is likely to fail in any kind of immediate or catastrophic way. It’s current and past deficiencies are primarily of a kind that, given cryonics’ fundamental lack of normal market feedback, will not be evident to cryonicists, let alone to the public, even if pointed out to them. The legacy of the Cryonics Society of California (CSC) is proof of that reality. So, that’s not what I’m saying.

What I am saying is that there are certain infallible signs that an enterprise is in deep trouble, and while perhaps not in immediate danger of going under, is only going to continue to exist under highly favorable conditions. I’ll be quite specific in a moment, but I want to a spend few moments more on what is the really the more important point I have to make.

I’ve traveled the world and visited just about every kind of enterprise imaginable. Whether it is a restaurant Florence, a medical clinic in Hyderabad, or an ICU in Mumbai or Moscow, there is often this unmistakable gestalt (stench) of a profoundly dysfunctional business which is evident within minutes of being on the premises. Please note that I am not saying that all failing enterprises exhibit this aura, because I’m sure they don’t. Enron probably seemed in fine fettle until just before the end. But I am saying that when that ambience is present, the enterprise is in extremis. Under normal market conditions that would mean that you could reasonably (soon) expect the doors to be shuttered (or the floor to be removed, in the Middle East). The exceptions are small town businesses that constitute micro-monopolies, government operated facilities in the undeveloped world, and occasionally, religious orders or other institutions in terminal decline, but who have a trust fund or other stipend to sustain them.

While in many important ways Alcor is the descendant of Cryonics Society of New York (CSNY) and the no-nonsense, tell like it is approach to cryonics of Curtis Henderson, this is not by any means the full picture. CSNY had perhaps half the paradigm right. The other half that came to constitute the “mature” Alcor approach of the 1980s was pioneered by Fred and Linda Chamberlain, and was one of the Alcor assets already in place, if dormant, when IABS and I arrived on the scene in 1981. That approach was a clear acknowledgement and understanding that cryonics was an experimental procedure, that Alcor was a mutual aid organization, and that recruiting members who were also experimental subjects, was not the same as selling cryonics to customers.

There was, in fact, a strong aversion to marketing cryonics as an ordinary product, or even as a “regular” medical treatment. A consequence of this attitude was that everyone who interfaced with the public, until shortly before I left, had an almost fanatical attitude about how signing up should be communicated to the member. The interesting, and indeed remarkable thing about this is that I do not ever recall doing any training or any scripting of how to handle callers who were prospective members, or who were gathering information for same. It was just something that was “organic” and a part of Alcor’s small, but very well defined corporate culture.